GLASS PRODUCTION

The key accessory that embellishes your shower rooms is undoubtedly your shower cabins. So, how do you achieve quality and elegance in your shower cabin? Bevel's answer to this question is 'glass.' While providing alternatives in the glasses used in your shower cabins, Bevel also offers service with a healthy and durable glass portfolio. When designing shower cabins that appeal to your taste and aesthetics, we do not compromise on the quality of the glasses we use. The glasses used by Bevel are patented products of Şişecam, ensuring both quality and a variety of options in terms of colors and models for the glasses in your shower cabins. You can customize not only the model of your shower cabin but also the glasses of your shower cabin with Bevel quality.

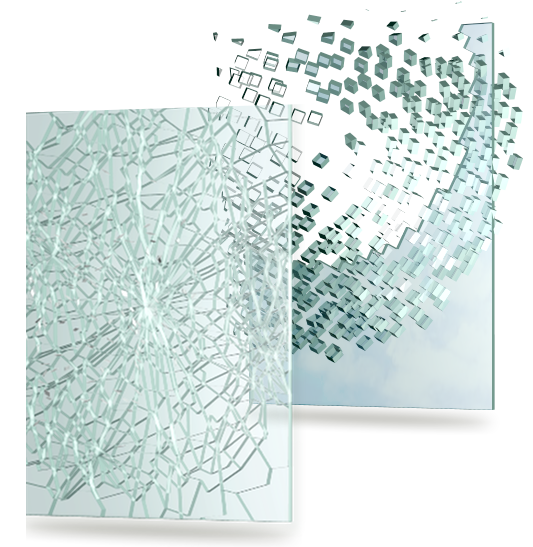

TEMPERED GLASS

Today, the best decision in terms of cleanliness and health in shower cabins is the use of glass. So, what do we know about glass properties? Bevel offers you options for shower cabin glass. Bevel uses tempered glass in your shower cabins, which are indispensable for bathrooms. So, what is tempered glass? The glasses we use in daily life are sensitive and have the potential to break at any time and harm us if broken. Therefore tempered glasses, unlike the glasses used in daily life; It is obtained by applying heat treatment to the glass to make it resistant to breakage, cracking and melting. Temper is obtained by giving 600-700 centigrade heat to the cast glass and then sudden cooling with air. In this way, very durable, thick glass is obtained; In case of glass explosion, injury is minimized. In this process, the internal stress is reduced by baking the glass and the reduced stress spreads throughout the glass. Glass with a reduced stress level is spilled as salt and ice rather than as pointed pieces that could harm people in case of breakage or explosion. For this reason, tempered glass is considered unbreakable and safe glass among the public.

Tempered glass is five times stronger than standard glass. These glasses, called safe glasses, are used in many areas of our lives - cars, ovens, glass doors-furniture, refrigerators, exterior windows, etc.

It is undoubtedly a fact that tempered glass produced with Bevel quality will be very attractive to you because it is much more durable than normal glass. In addition, it is a perfect choice because it minimizes the danger in case of breakage.

LAMINATED GLASS

Don't you want the glass in your shower cabins to explode, break or spill in any way? Then you can choose Bevel's laminated glasses. So what is laminated glass? Unlike normal standard glasses, laminated glasses consist of at least two glass plates. It is also produced by placing polyvinyl butyral (PVB) between these two glass plates. All layers are pressed under heat and pressure and turned into laminated glass. Laminated glass is reliable just like tempered glass and does not disperse in case of breakage or cracking. Therefore, in cases where laminated glass cracks, it can continue to be used as it does not pose a danger while the glass remains intact. Laminated glass, which has insulating properties in terms of sound and noise, is strong and durable in terms of security, and although it consists of different layers, it also has a stylish and aesthetic appearance as a single glass after being combined with heat and pressure.

The colors of laminated glass have the potential to adapt to the environment with smoked and bronze options. With these features, it also appeals to a wide range of uses. Since laminated glass guarantees high security, it is used in shopping mall showcases, hospitals, hotels, etc. It is used everywhere.

NEVRULLY GLASS

Bevel's alternative glass model is ribbed glass for a quality and unique appearance that you can use in your shower cabins. In addition to its durability and quality, it appeals completely to your style with its aesthetic and minimalist crystal-shining clear appearance and design. In addition, privacy protection is created with the pattern used on the glass, preventing the other side from being seen clearly. In addition to the possibility of using the color you want in the ribbed glass model, an optional multiple-choice design portfolio is also available.

ALUMINUM PROFILE

Aluminum profiles are a very frequently used tool in shower cabin systems. The first reason why these profiles are used is to prevent water leakage. Bevel also uses aluminum, a strong and flexible material, when providing you with shower cabin service. The most important factor in using aluminum profiles in your shower cabins is that the material is light and resistant to external influences. Where does Bevel use aluminum profile? In addition to the rail cabin systems of your shower cabins, it is also used to cover structures that receive water. In addition, aluminum allows us to obtain different models due to its easy processing feature. Moreover, these profiles are a very healthy material and help create a spacious environment by allowing your bathrooms to breathe.

When we consider the image, the thickness of the aluminum profiles is 2mm. This thickness is sufficient to prevent water from escaping in your shower areas. In addition, Bevel mounts the profile by pulling silicone to fix it and ensure sealing.

In addition to the aluminum that Bevel offers you with its quality, it is resistant to the hardest impacts, and you also have the opportunity to choose different color options for your profiles.

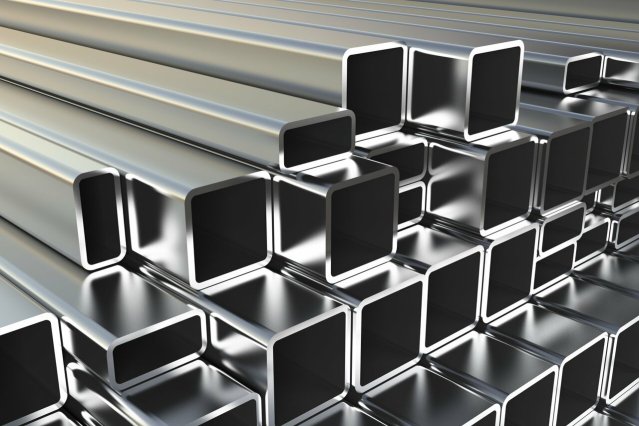

STEEL PROFILE

Another alternative Bevel offers for your shower cabins is steel profiles. Steel profiles are also called stainless steel. Stainless steel profile in addition to being quite durable, it also maintains its properties at high pressure values and ensures customer satisfaction. Bevel uses stainless steel material in many areas such as box profiles, shower cabin frames and flat systems. The 316 stainless steel we use is preferred in shower cabin areas because it is resistant to water and does not pose any problems such as rusting. In addition, we serve you with Bevel quality, whose steel material is easy to clean and has special protection against rust. We offer you better service by using this material, which is long-lasting, shiny for a lifetime, and highly resistant to crushing and bending, in your shower cabins. If you want to get rid of the ordinary in your shower cabin, have a lifetime of use, and want a stainless shower cabin with the newness and cleanliness of the first day, then you should choose the steel profile from Bevel.

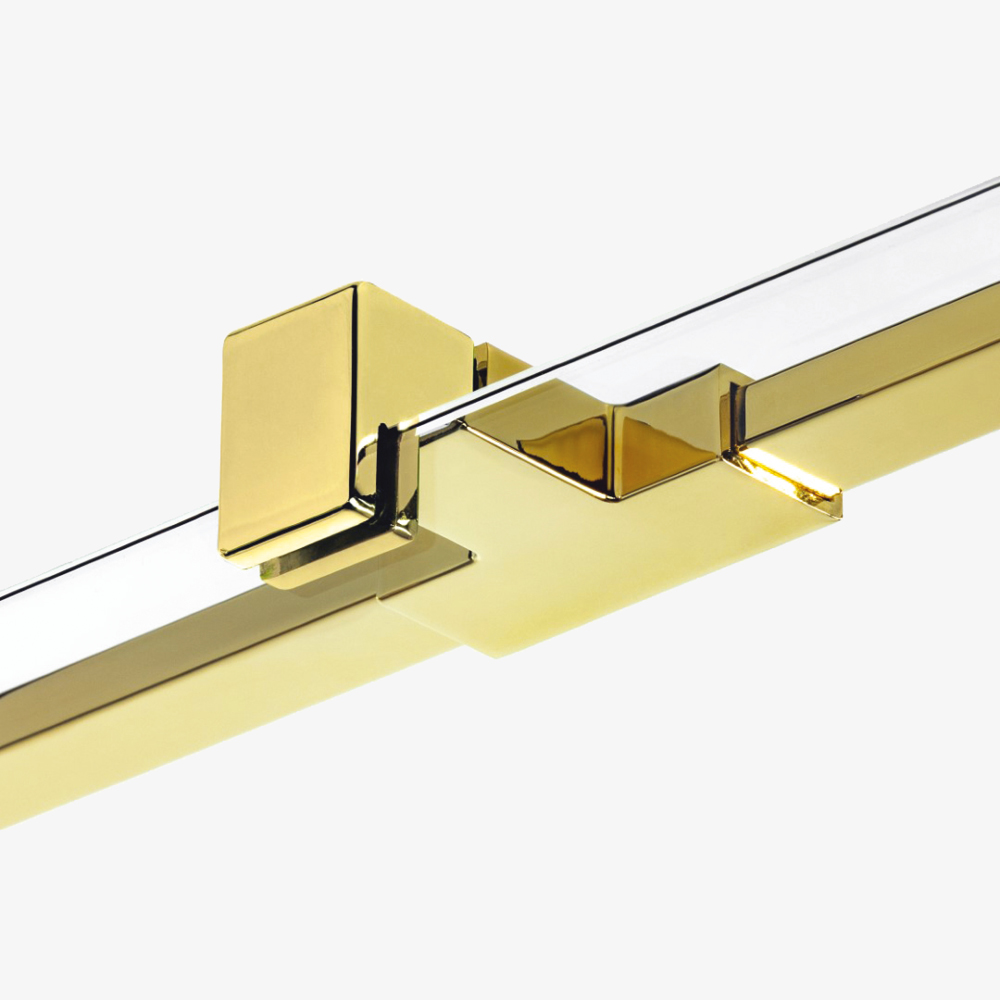

RICE PROCESSING

Brass is a durable and shiny material that started to be produced in ancient times. One of the areas of use today is shower cabin accessories. While Bevel offers you the best quality shower cabin, it also attaches importance to the quality of your accessories. Materials made of brass have the characteristics of strength and durability and are resistant to wear even when used in corrosive environments. At the same time, brass is resistant to corrosion. This makes it an ideal choice for applications that require exposure to water or other chemicals.

Brass is the general name of the yellow colored alloys obtained by adding zinc to copper. There are also tin, lead, nickel, manganese, iron, aluminum, arsenic, antimony and phosphorus. Rice is long-lasting due to the materials it contains. In terms of appearance, brass is an ideal material to capture the elegance in your shower cabin, as it does not hide its eye-catching quality. Due to all these features, brass materials are frequently used in industrial applications and have many useful properties. As Bevel, we serve you with brass materials that we do not compromise on quality.

COLOR COATING

Do you want to see colors that reflect you and your style in your shower rooms? Then the right address is Bevel. We offer you shower cabins in the highest quality colors with multiple color options. How do we obtain colors in shower cabin profiles and accessories? While obtaining various colors, coatings are made using the PVD (Physical Vapor Deposition) method to increase the durability and performance of the colors. PVD coatings are formed in high vacuum by converting the metal into vapor and simultaneously adding a reaction gas. Using different temperatures (up to 200-500°C) we can create layer thicknesses of 2-8 µm.

Arc process technology is used to achieve excellent adhesion strength without loss of hardness, distortion or change in the microstructure of the base material. Bevel offers you a wide range of custom color portfolios that will ensure that you will not have any problems such as paint leakage etc. for many years. It provides service with titanium coatings that you will not experience any problems with. While providing the color in your accessories, we take care to use harmless materials without ignoring your health.